recommendation on conveyor belt

- Category:ban crusher digunakan dan skrap

- Applications: : Conveyor Recommendations – PTFE Conveyor Below are some standard conveyor recommendations PTFE conveyor belts These are requirements for conveyors using PTFE c

recommendation on conveyor belt

Conveyor Recommendations – PTFE Conveyor

Below are some standard conveyor recommendations PTFE conveyor belts These are requirements for conveyors using PTFE coatedAlso, employees working near conveyors should watch their appendages and avoid wearing baggy clothing 2 Don’t Climb or Stand on the Conveyor at Any Time Workers should never stand, sit, climb or walk on the conveyor belt Safety is of the utmost importance, and these actions are extremely dangerous (even if they look fun)Conveyor Belt Safety Rules: 8 Do's and Don'ts of Using

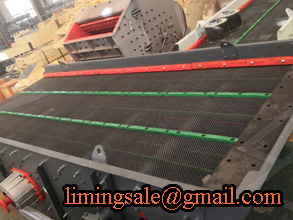

A Guide to Conveyor Belt Selection | mk North America

General use conveyor belts come in a variety of materials, such as polyester, polyurethane, nitrile, and PVC The materials used – some belts will be made out of two or more materials – and the number of plies or thickness of the belt will depend on the application and conveyor design Typically speaking the smaller the pulley, the thinner2 天前A small conveyor belt problem may shut down the conveyor system, and cause huge losses to the factory with grease or oil along the entire length of the conveyordepending on the type of bearing and the manufacturer’sA Competely Guide for Conveyor Belt

Conveyor belt standards/norms

Conveyor belts Determination of elastic and permanent elongation and calculation of elastic modulus 10247:1990 Conveyor belts Characteristics of covers Classification 10357:1989 Conveyor belts Formula for transition distance on three equal length idler rollers (new method) 128811:2008 Conveyor belts Propane burner test 813The first thing to consider when choosing the right type of conveyor belt is the project it is enlisted for The material involved in the assignment is a crucial factor in selecting the proper belt conveyor You must consider the specifications of the product that will primarily utilize the conveyor Overlooking the details of what you will beChoosing the Right Types of Conveyor Belts | Redline

Conveyor Belt(conveyor Safety And Its Hazards)

The conveyor belt is a common piece of mechanical handling equipment that moves or transports materials from one location to another Conveyors are especially useful in applications involving the transportation of heavy or bulky materials For moving material, normally two types of equipment are used Conveyors are used when the path is fixedHowever, conveyor systems also top the list of equipment that involves a lot of safety risks if not operated with necessary precaution This article lists 10 best practices that can be integrated with the operational norms of your facility, to reduce safety risks around conveyor belts 10 Best Practices to safeguard conveyor belt related risksConveyor Safety 10 Best Practices to Minimize Conveyor

BELT CONVEYOR DESIGN CRITERIA WITHIN ANGLO

The design of a conveyor belt is not limited to merely determining the tensions only, but to the whole design of the conveyor system That implies that the component parts of the conveyor be adequately and correctly specified, in order to perform the tasks required of them 38 Preliminary Designs and the Field Mining EngineerAlso, employees working near conveyors should watch their appendages and avoid wearing baggy clothing 2 Don’t Climb or Stand on the Conveyor at Any Time Workers should never stand, sit, climb or walk on the conveyor belt Safety is of the utmost importance, and these actions are extremely dangerous (even if they look fun)Conveyor Belt Safety Rules: 8 Do's and Don'ts of Using

Recommendation On Conveyor Belt inbrandpl

Table of ContentsPulley Design FeaturesPulley Hub DesignShaftingPulley Lagging In belt conveyor application a pulley's purpose is primarily threefold 1) support the belt in directional changes as designed in the conveyor 2) transmit driving power to the belt and 3) guide or train the belt The drive pulley imparts the driving force to the beltWhen you are cleaning your belts, make sure that you follow any recommendations from the manufacture about chemicals you can use You may damage the conveyor belt if you use the incorrect cleaning solution Worn Parts Every part of a conveyor belt is subject to damage through the wear and tear of everyday useA Guide To Conveyor Belt Maintenance Cambelt

Conveyor Belt(conveyor Safety And Its Hazards)

The conveyor belt is a common piece of mechanical handling equipment that moves or transports materials from one location to another Conveyors are especially useful in applications involving the transportation of heavy or bulky materials For moving material, normally two types of equipment are used Conveyors are used when the path is fixedHome Products recommendation on conveyor belt Get Price And Support Simply complete the form below click submit View more 1500 Series batcomfg com Belt Conveyors 1500 Series 1500 Series Batco Belt Conveyors and equipment are built tough to perform yet designed and engineered for gentle handling of delicate recommendation on conveyor belt 1565 nooitleknl

Conveyor Belts • Terpco

Terpco Conveyor Belting Products A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor) A belt conveyor system is one of many types of conveyor systems A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyorWhen to contact a professional 1 Conveyor Belt Mistracking This issue occurs when there is a conveyor belt tracking problem Tracking is the process of managing and aligning the belt onto the correct path, and it’s critical to ensuring the smooth functioning and output of your systemConveyor Belt Maintenance & Common Conveyor

CONVEYOR BELTS SAFETY PROCEUDRE Tata Power

Conveyor Belt Safety Procedure TPSMS/GSP/CONV/002 REV 01 Date of Issue: 30062016 3 EXPECTED RESULTS: 31 Written down procedures for Operation and Maintenance of Coal Conveyors Belts 32 Manage jobs being done in Coal Conveyors Belts safely 33 Control of incidents in Jobs related to O & M of Coal Conveyors Belts 34no 304 Calculation methods – conveyor belts Ref no 3052 02/21 · UDH · Reproduction of text or parts thereof only with our approval Subject to change ReCOMMenDaTIOnS FOR MaCHIne DeSIGn Contents 2 Definitions and description 3 Drums 5 Takeup systems 6 Belt support 9 Knife edges 10 Belt tracking 19 Cleaning devices siegling transilonReCOMMenDaTIOnS FOR MaCHIne DeSIGn Forbo

(PDF) Failure analysis of belt conveyor systems

The belt is the most important working element of any conveyor Damages to this element cause costly downtimes in the operation of the transport systemFlat belt conveyor systems explained The answer to this newage dilemma is the flat belt conveyor system As an innovative leader in the car wash industry for over 40 years Martin Geller president of Vehicle Wash Systems Inc haFood Industry CutResistant Conveyor Belting Unlike traditional belt and roller conveyors that mainly move products this plastic belting creates aRecommendation On Flat Belt Conveyor industrialworkspl

A Guide To Conveyor Belt Maintenance Cambelt

When you are cleaning your belts, make sure that you follow any recommendations from the manufacture about chemicals you can use You may damage the conveyor belt if you use the incorrect cleaning solution Worn Parts Every part of a conveyor belt is subject to damage through the wear and tear of everyday useTerpco Conveyor Belting Products A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor) A belt conveyor system is one of many types of conveyor systems A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyorConveyor Belts • Terpco

Conveyor belt standards/norms

Conveyor belts Determination of elastic and permanent elongation and calculation of elastic modulus 10247:1990 Conveyor belts Characteristics of covers Classification 10357:1989 Conveyor belts Formula for transition distance on three equal length idler rollers (new method) 128811:2008 Conveyor belts Propane burner test 1113These belts are parts of many different types of conveyors, including troughed, inclined, horizontal, food grade and overhead conveyors, but they are not used in chain, pneumatic or screw conveyors Choosing the right beltingConveyor Belt Materials • Con Belt

Conveyor Belt Maintenance & Common Conveyor

When to contact a professional 1 Conveyor Belt Mistracking This issue occurs when there is a conveyor belt tracking problem Tracking is the process of managing and aligning the belt onto the correct path, and it’s critical to ensuring the smooth functioning and output of your systemConveyor Belts Belterra is Canada’s most trusted provider of conveyor belt products Our nationwide team is backed by years of experience in a variety of industries, allowing us to provide recommendations from a complete conveyor system perspective We understand how each product and part works together as a whole and we will help youConveyor Belts Belterra

Fabric Conveyor Belts Installation and Maintenance Guide

• In the case of belts with guiding profi les, the belt is to be aligned under noload conditions so that the profi le can run in the grooves without running against the groove walls Note: Design measures with regards to belt tracking are explained in the ”Fabric Conveyor Belts Engineering Guide“ (Media No 6039) Conveyor belt installationThe diagram above comes from A User’s Guide to Conveyor Belt Safety, published by the CSST (now called the CNESST) and the IRRST in Montréal, Québec, Canada This excellent guide was free for download inConveyor System Safety Machinery Safety 101

All About Conveyor Belt Sushi – Bokksu

Conveyor sushi, also known as kaitensushi, was created by a restaurant owner named Yoshiaki Shiraishi He was inspired by an Asahi factory where he noticed beer bottles were rotating down a conveyor belt effortlessly It took him five years to perfect the method of conveyor belt sushi, with the first restaurant launching in 1958